One question no one wants to ask or hear is, “Why did my paver project fail?” Unfortunately, from time to time, projects do not perform as well as intended. It is important to learn from these projects to avoid similar challenges in future projects. Pavers can fail over time for a variety of reasons.

In this second post in our two-part series on choosing the right material to put under pavers, we look at what causes paving project failures. We also address some of the most common questions we hear about natural stone pavers.

Paver Failure – What Lies Beneath?

In a major urban area in the upper Midwest, a large area of granite pavers began cracking 10 to 15 years after installation. The cracking pavers are located along a 12-block section of the city’s downtown, well-known for its shopping, dining and pedestrian experience. Typically, an application like this should perform for 30 to 50 years with minimal maintenance. However, the climatic conditions of the area combined with insufficient drainage of water at the surface accelerated the aging and subsequent breakdown of the pavers.

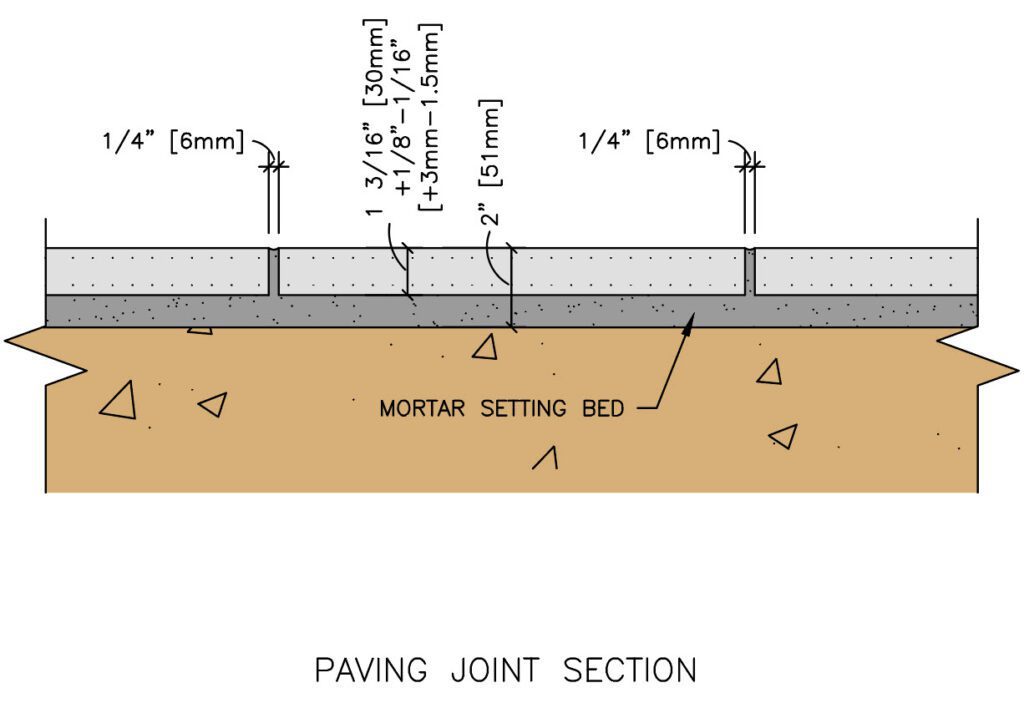

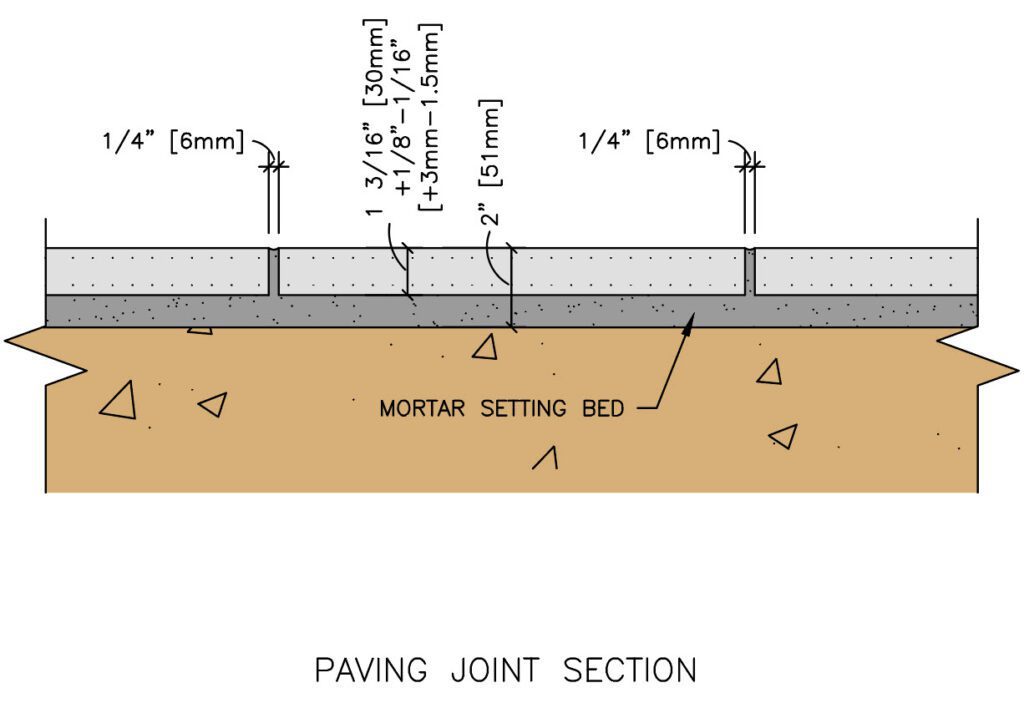

Over several years, small voids and cracks developed in the mortar joints between the pavers, enabling water to infiltrate the mortar base. With consistent and repetitive exposure to moisture, the mortar became saturated. After the expansion and contraction of hundreds of freeze-thaw cycles, the mortar broke down into a dusty powder. Water eventually displaced the powdery mortar, leaving voids in the subgrade.

The initial perception by many responsible for maintaining the surface was the granite was cracking and failing on its own. It was not until the broken pavers were removed that the gaps and voids beneath the paver exposed the underlying issue. Without an adequate base, the pavers were no longer able to support the weight and pressure being placed on them from above.

Since the plaza area encompassed thousands of square feet, the deteriorating pavers became a maintenance obstacle over time. The plaza’s deterioration would have been slowed or avoided altogether had drainage issues not occurred. It is also possible if a more flexible and hydrophobic setting system, such as a bituminous paving bed, had been chosen, the outcome could have been different.

Granite paving is arguably the most durable surface material for standing the test of time. However, if environmental factors result in a subgrade base being unable to uniformly support the stone above it, the likelihood of granite paving reaching its intended performance will be compromised.

Ultimately, the life of your pavers will depend significantly on the material placed beneath them. Using the wrong paver base or installing improperly can lead to cracked and uneven pavers. If you want your pavers to last, a strong foundation is crucial.

Finishing the Job

Once the setting bed method is selected, the best finish for the paving surface must be considered, especially when preventing slips and falls in icy or wet conditions. Just like setting bed methods, there are several finish options for natural stone pavers, but thermal is the most traditional for pedestrian surfaces. It gives the stone a nice texture and holds up very well over time. It also meets many slip-resistance testing requirements.

Depending on the stone used, the environment it is in, and the volume of foot traffic it receives, the aggressiveness of the finish may need to be adjusted. Knowing the environment both during and after installation will make for a natural stone landscape that will not only be functional but also beautiful.

If you have questions about your current or next paving project, please contact Coldspring and connect with one of our experts.